Shifting from Legacy Systems to Modernized Operations for 3D Crystal

3D Crystal specializes in creating high-definition 3D memorabilia. They capture and preserve cherished memories with exceptional clarity and detail. As a pioneer in the industry, 3D Crystal distributes innovative technology and offers comprehensive training to entrepreneurs worldwide.

Industry

3D souvenirs, Retail

Market

Canada, Worldwide

Initial Release

2023

Overcoming ERP and CRM challenges of the legacy system

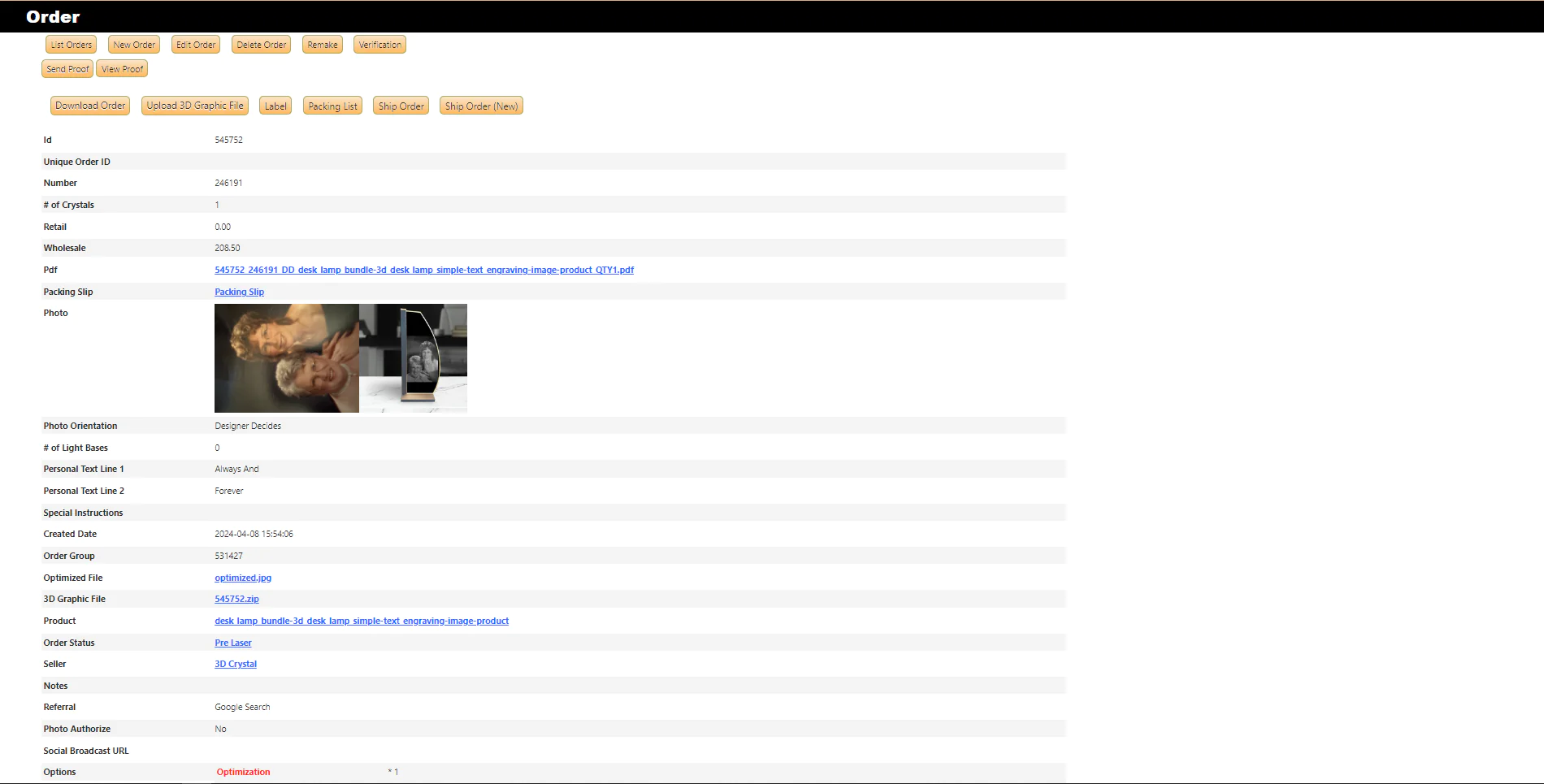

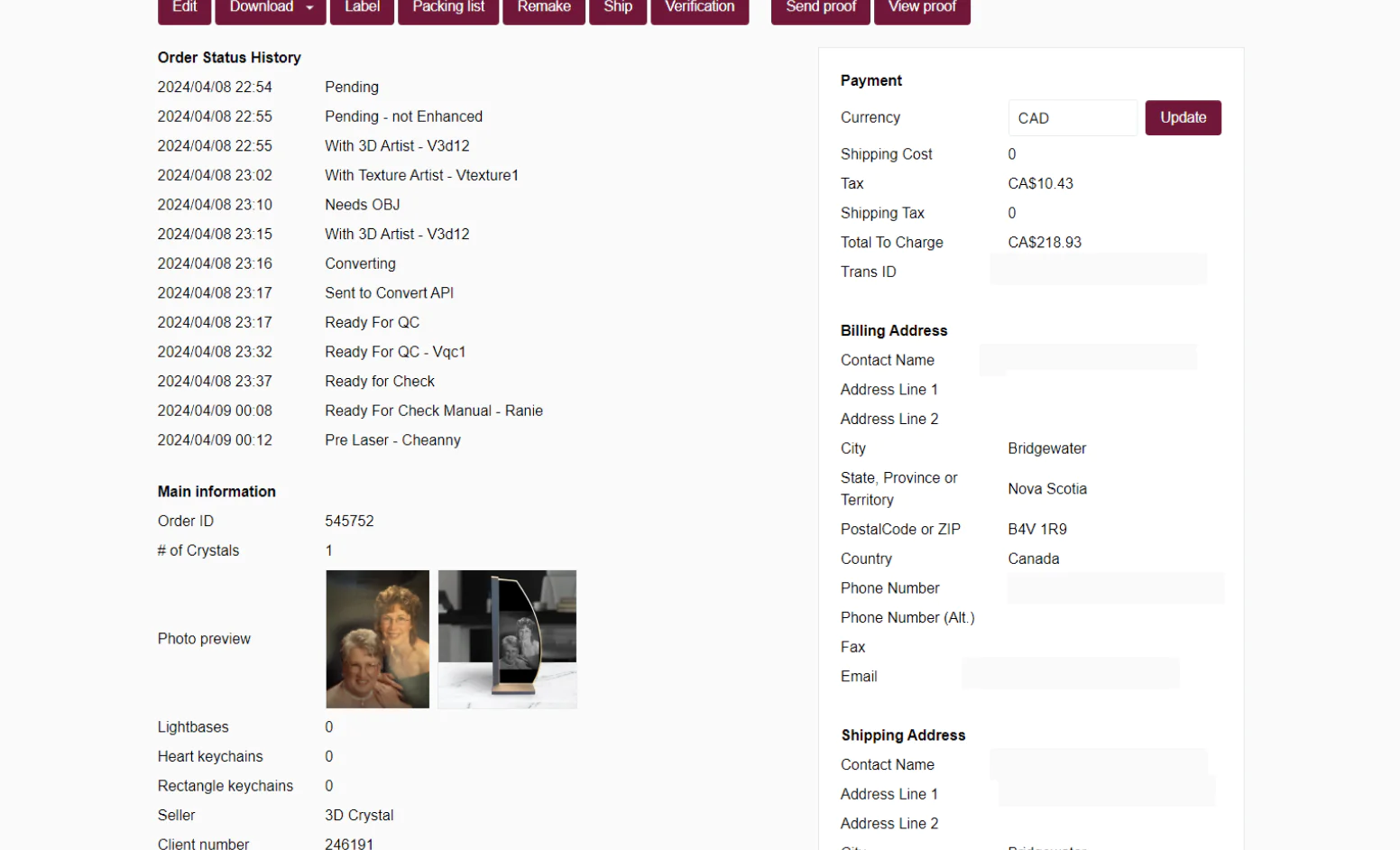

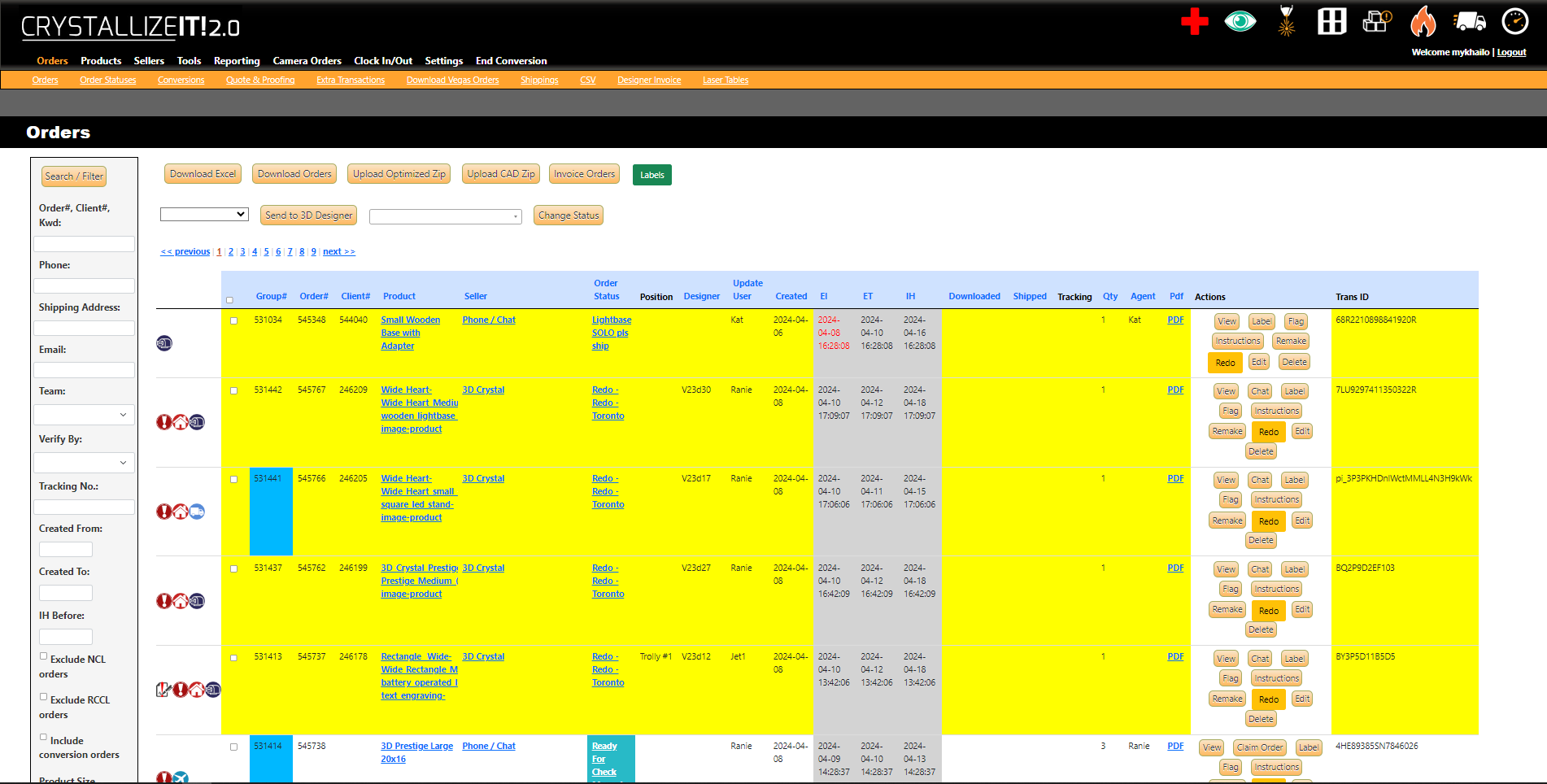

3D Crystal, a company with a long-standing presence in its industry, was grappling with a critical issue. Their ERP and CRM systems, which had been in place for 14 years, had become sluggish and unreliable.

Over the years, as they added new features to keep up with business demands, the system grew overly complex. This complexity resulted in a system cluttered with outdated features and an interface overwhelmed with unnecessary elements. All that greatly reduced its efficiency.

6 months

Duration

2 people

Team

Scrum

Methodology

Vue.js

Platform

Alva Commerce’s strategy for smarter, faster processes

Alva Commerce approached this by first conducting a thorough audit of the existing systems. It helped us to identify which features were essential and which were redundant.

So, our team:

- Thoroughly reworked the backend to streamline existing functionalities and improve overall system performance.

- Optimized the database structure to enhance data processing efficiency, reducing system delays.

- Implemented a new headless front-end architecture, which operates independently of the backend, enhancing scalability and reducing load times.

- Added some new features to the system, integrating seamlessly to meet evolving business needs without compromising on efficiency.

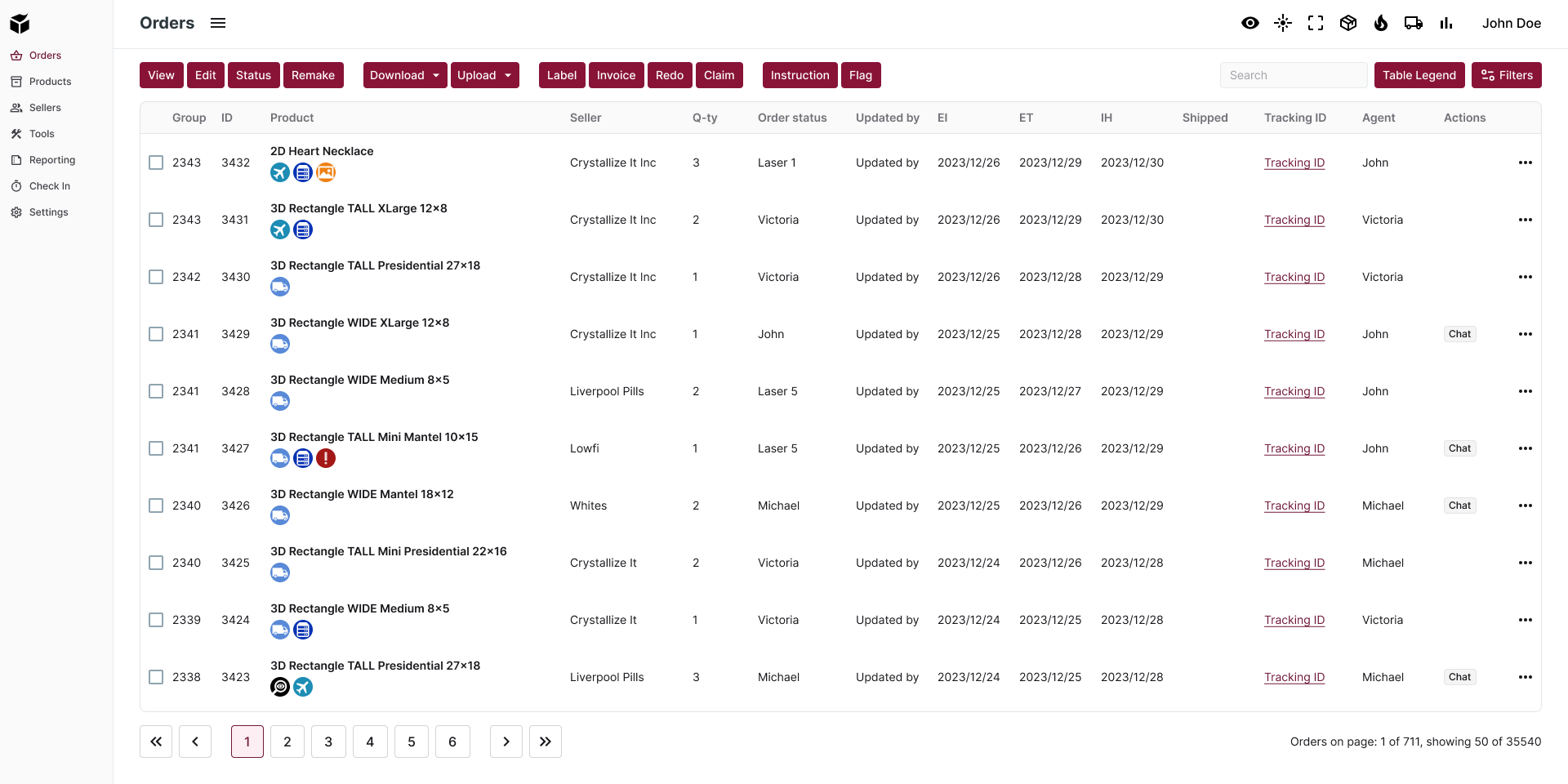

New front-end application: a fresh approach

Our team built a brand-new front-end application from scratch. We designed it to meet current user needs precisely. It’s connected to the backend via an API, allowing it to operate independently.

This separation ensures a smoother user experience and lets the backend focus more on complex business logic.

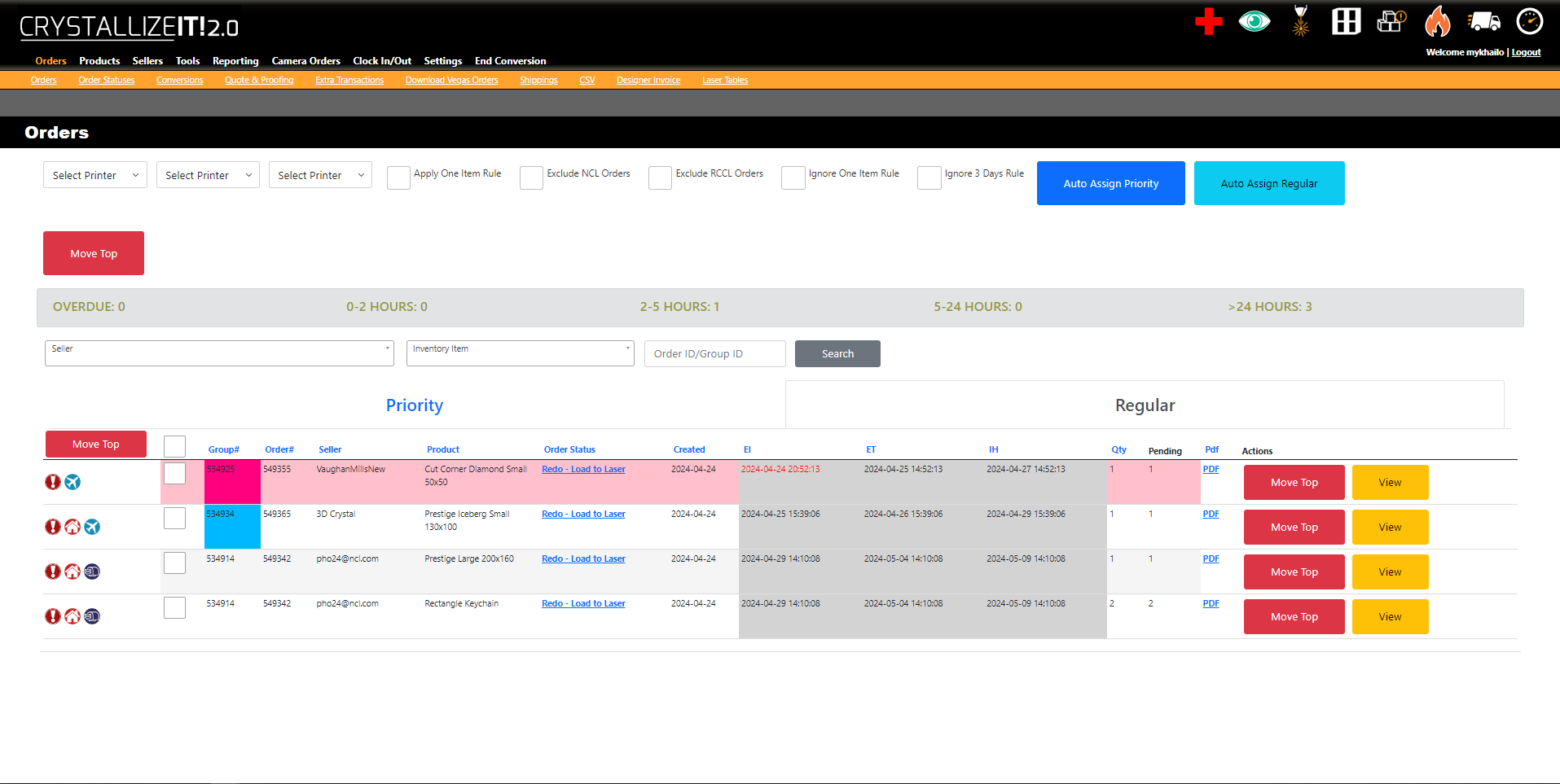

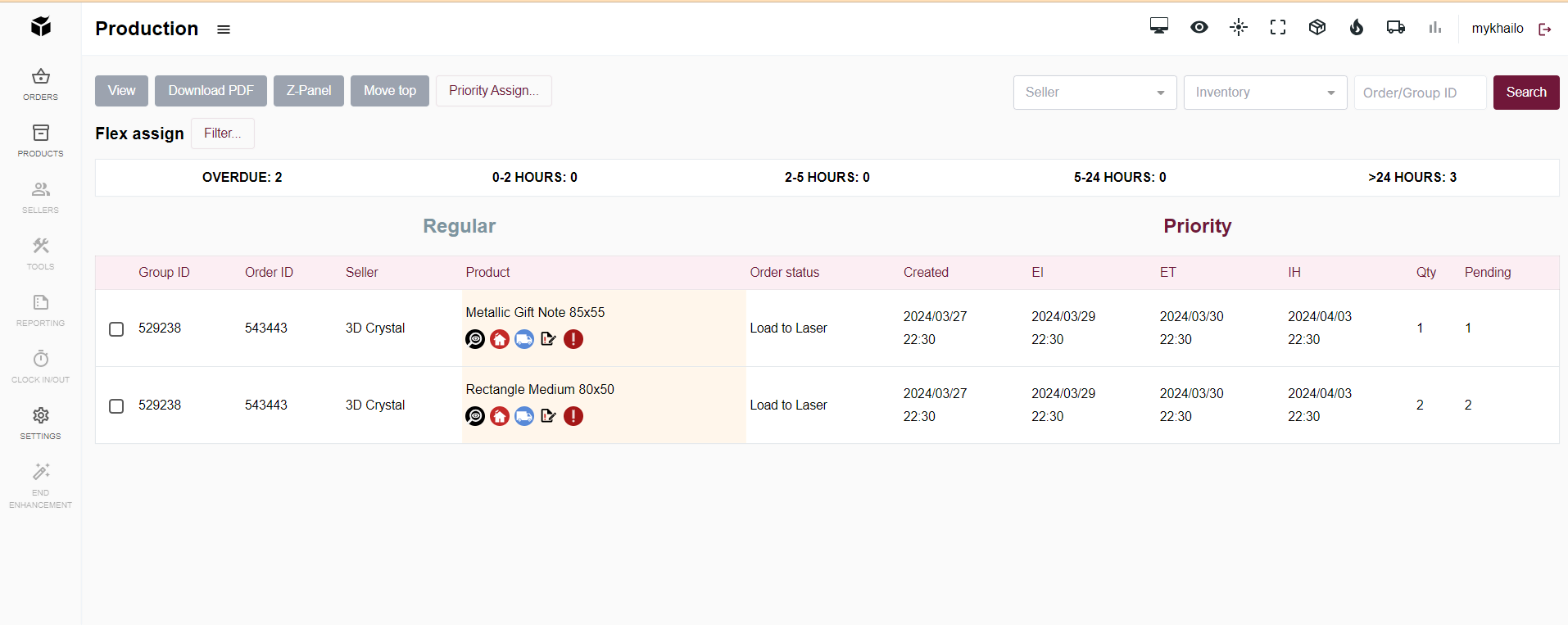

Streamlining production with auto-assigning

A key enhancement in the new front-end application for 3D Crystal is the “Auto-Assign” feature, which significantly automates the production process. This system automatically sorts incoming orders by priority.

Next, it assigns them to compatible lasers for production. It intelligently considers various factors such as product compatibility, current workload, and even the time of day.

This automation not only optimizes the production flow but also adjusts dynamically to ensure efficiency throughout the day.

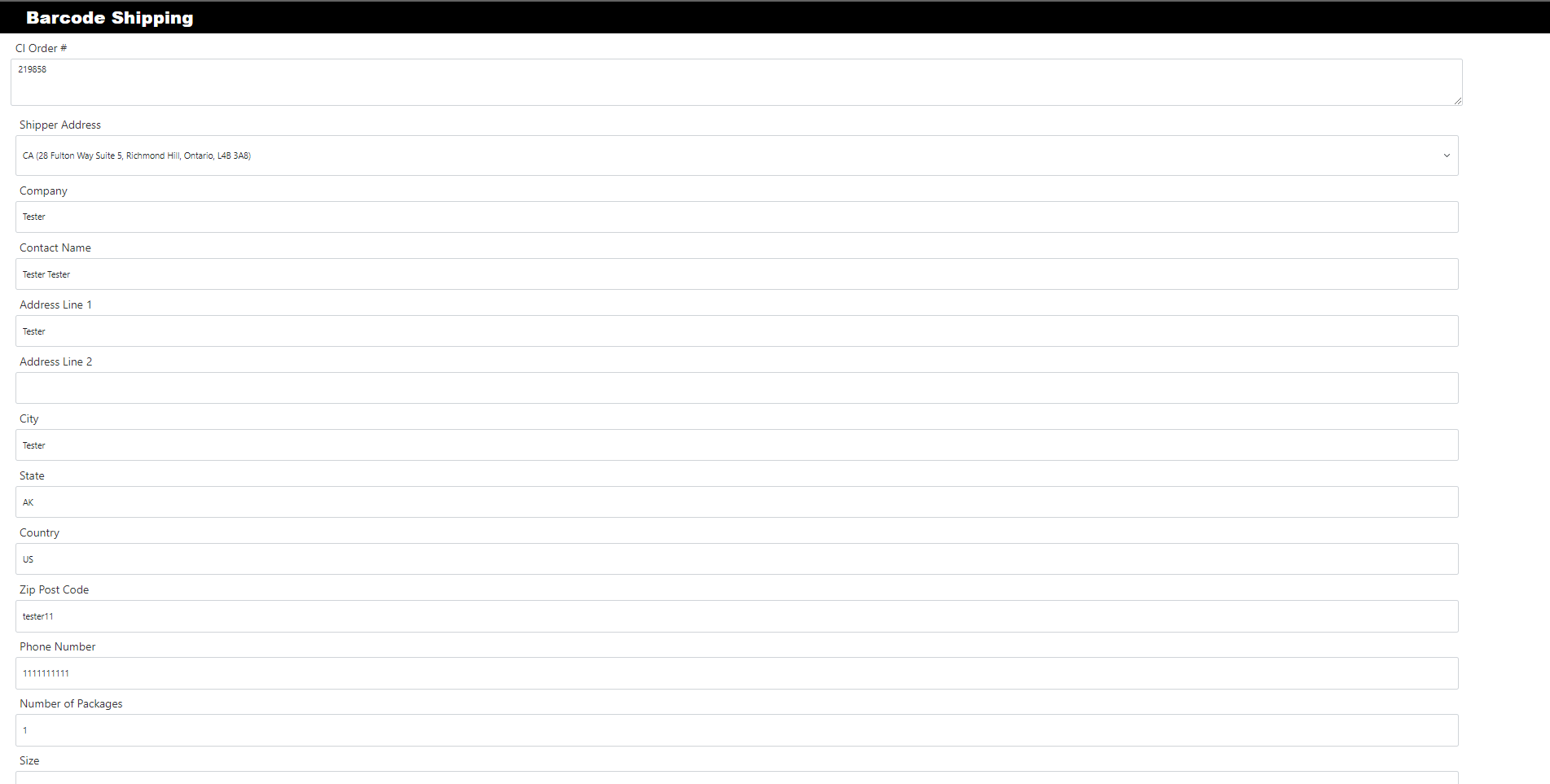

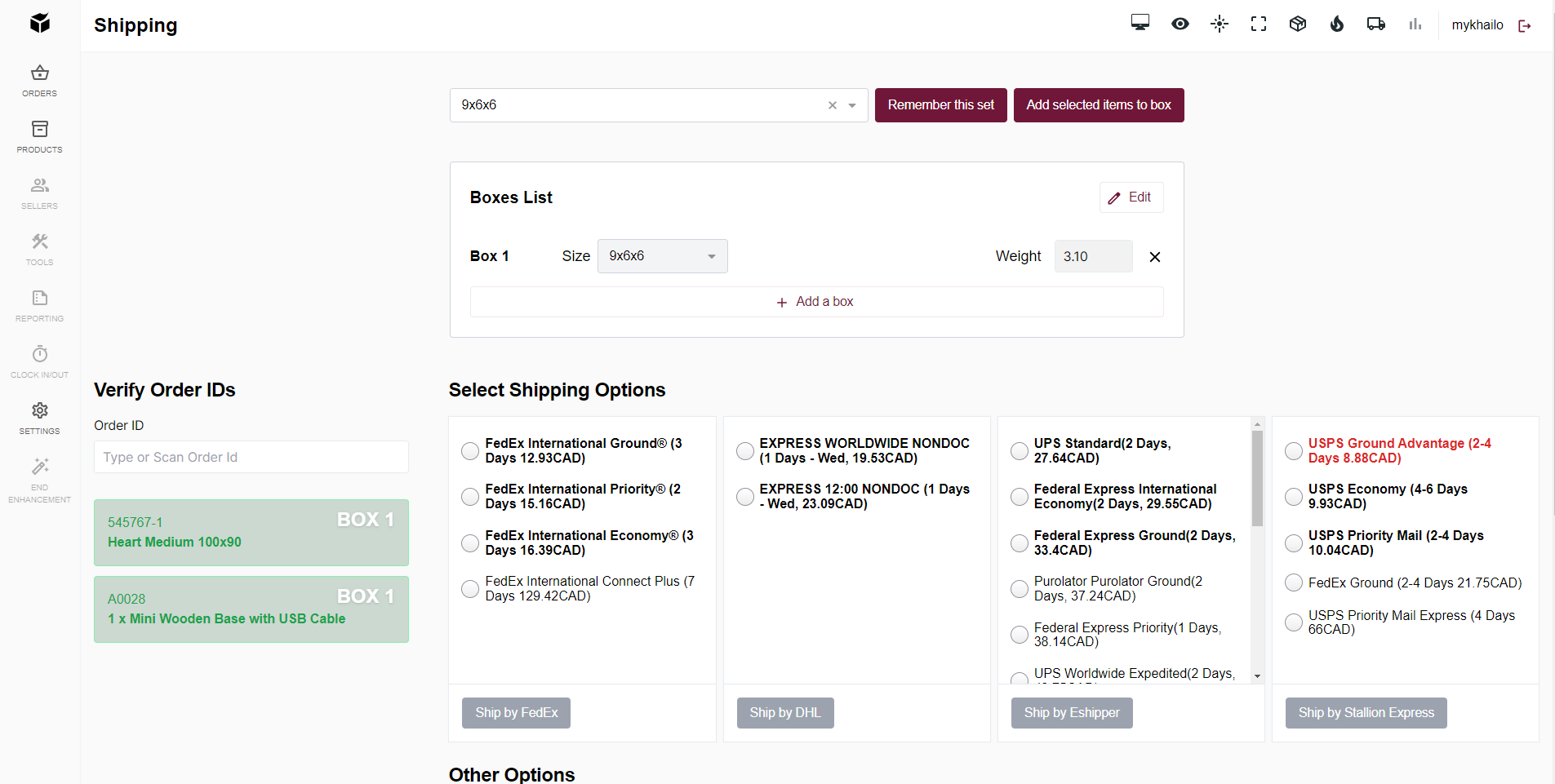

Enhanced shipping: smarter, faster, simpler

The new system at 3D Crystal has greatly simplified the shipping process. It intelligently predicts the optimal box size needed for a given set of products. If a particular product combination is new, users can manually select a box size and save this information for future shipments.

Additionally, as items are scanned for packing, the system automatically calculates and compares shipping costs from various carriers.

Next, it recommends the best option based on cost and priority. Should items not fit, the system allows users to effortlessly split the shipment into multiple boxes and updates pricing instantly. So, the entire shipping process is more efficient and user-friendly.

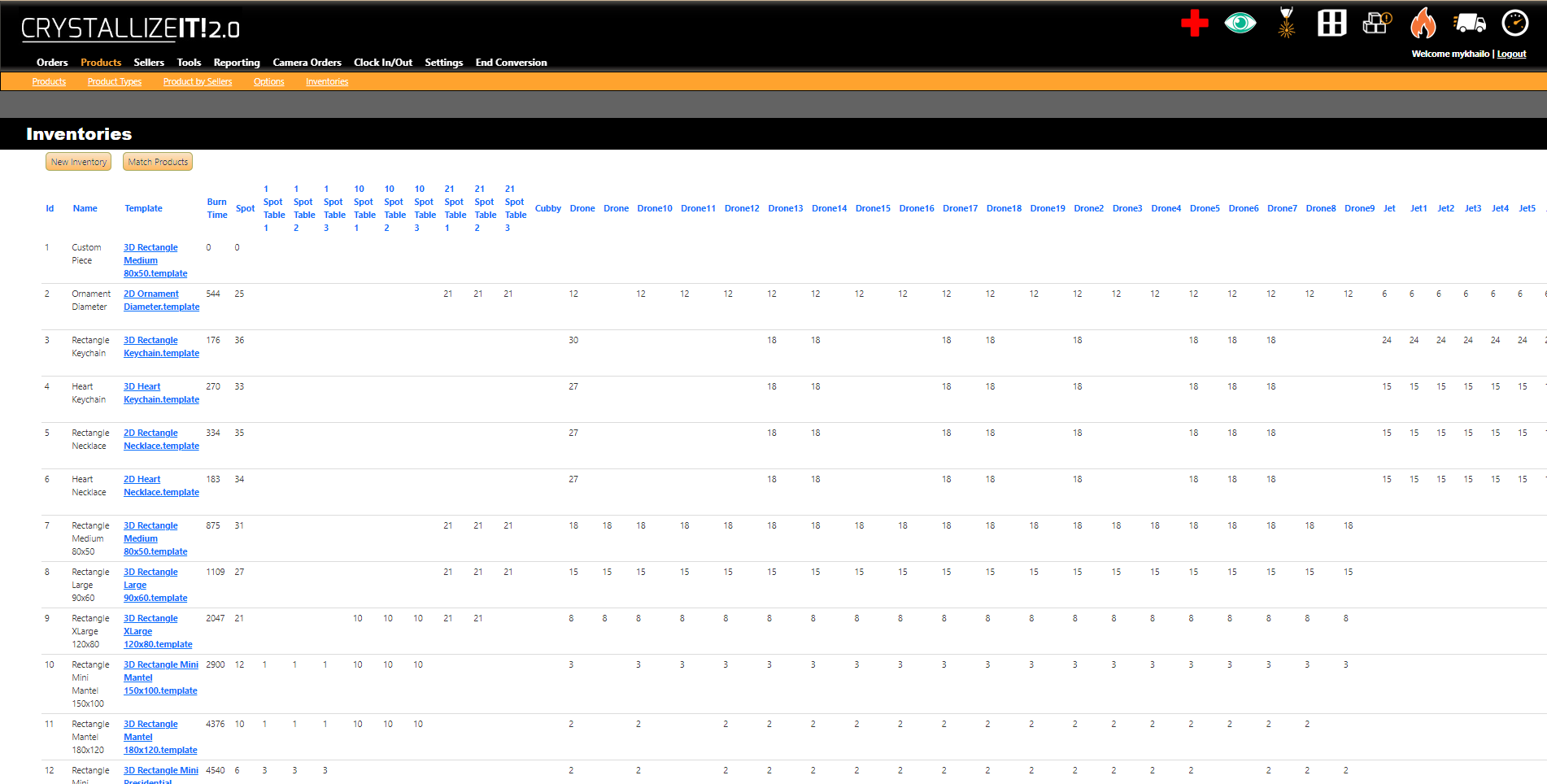

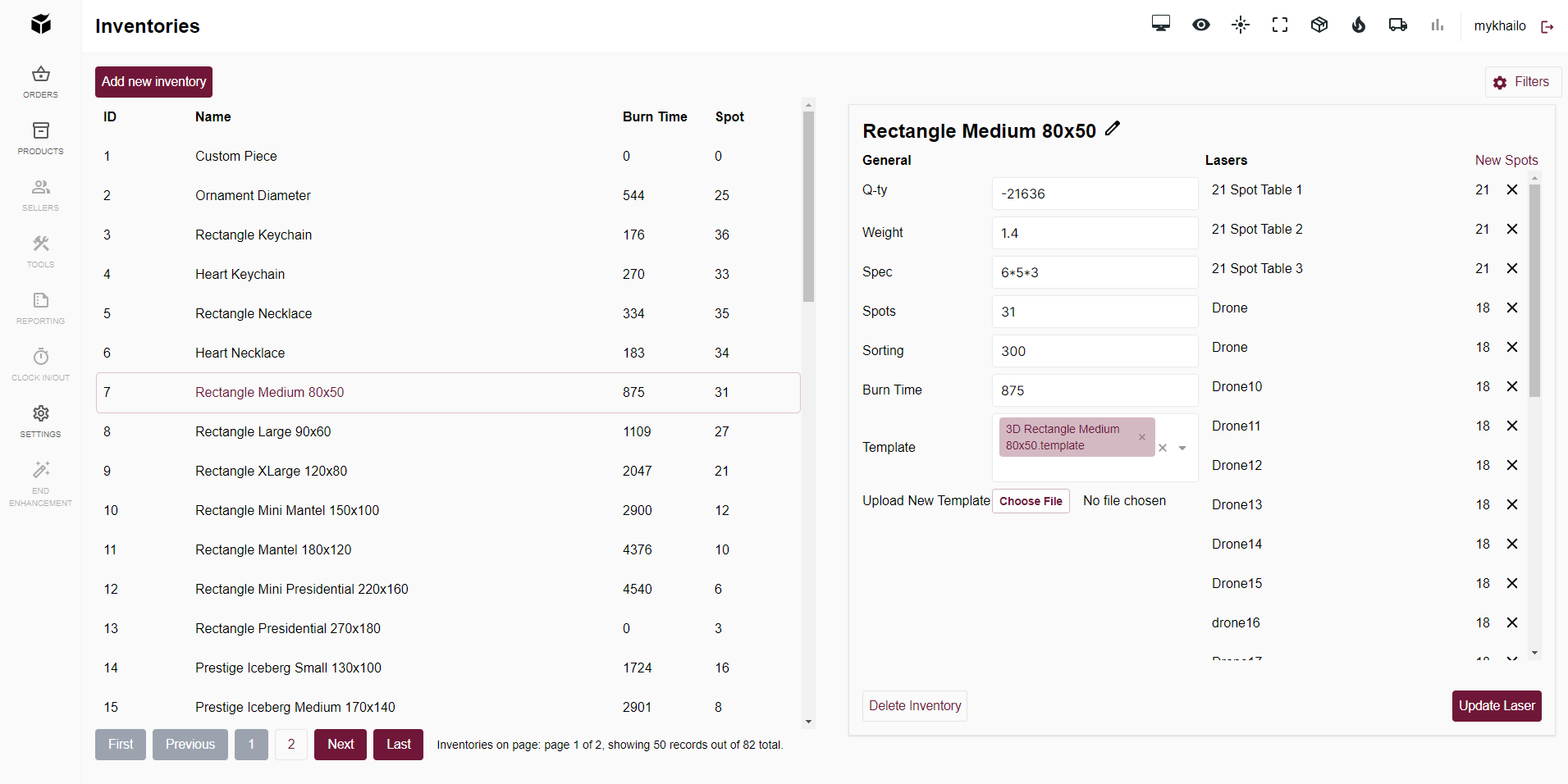

Improved usability and efficiency of the inventory page

We revamped 3D Crystal’s inventory page to tackle usability issues caused by an expanding list of products and lasers. The previous complex grid system was replaced with a streamlined configurator that combines product details and compatibility into one view.

Now, the interface displays only lasers compatible with a selected product, allowing for quick additions with just two clicks. This change simplifies navigation and speeds up the process of matching products with appropriate lasers.

Technical stack

Backend

CakePHP

MySQL

Frontend

Vue.js

Host

Amazon S3

New Relic

Integrations

Key results

Improved scalability and user experience

by revamping shipping, inventory, and order assignment.

Optimized production flow

by adding an algorithm for their splitting and timely processing of urgent ones.

Speeded up shipping by 3 times

by optimizing the user journey and their workflow.